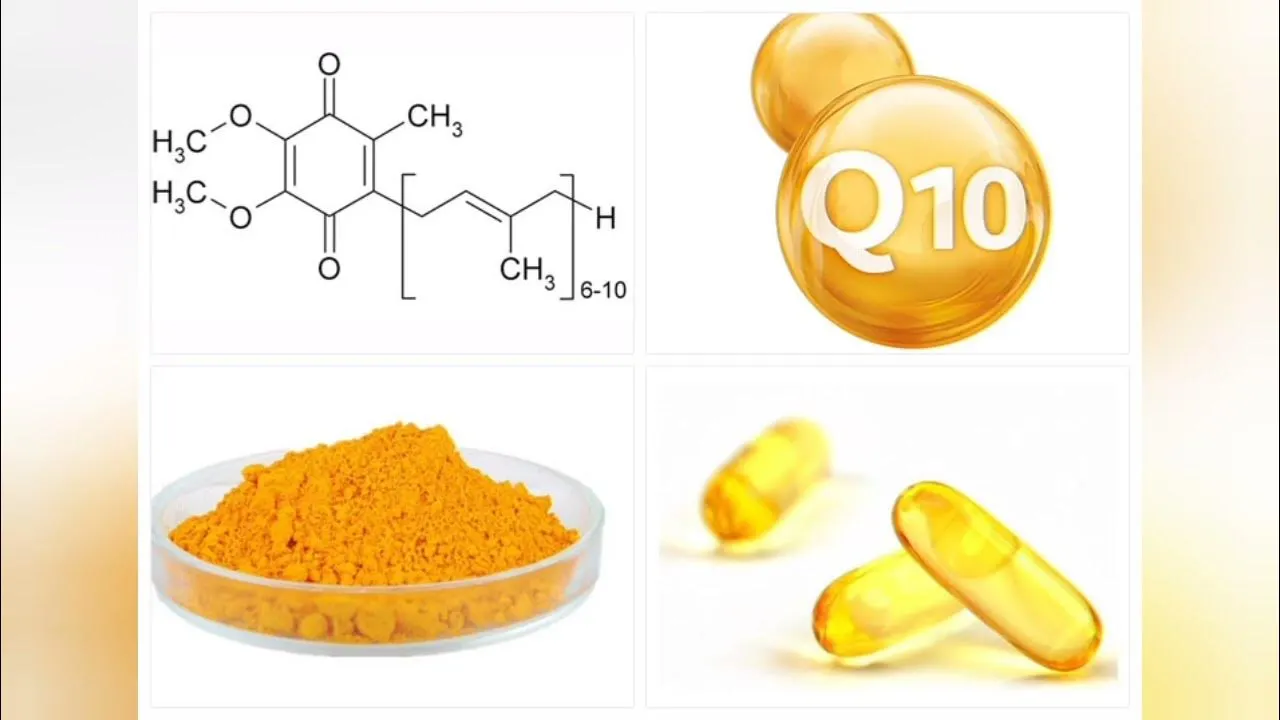

When it comes to nutraceutical research and development, great consideration must be given to the purity, bioavailability, stability, and regulatory compliance of the appropriate Coenzyme Q10 Powder Bulk. This comprehensive guide discusses essential issues that must be taken into consideration by research and development (R&D) teams, procurement managers, and formulators when acquiring ubiquinone powder for the production of supplements. Making sure that these characteristics are understood guarantees that the performance of the product will be at its highest while also satisfying strict quality standards in marketplaces all over the world. The process of selecting has a significant impact on the likelihood of successful formulation, the efficiency of manufacturing, and the effectiveness of the final product in applications related to energy support, cardiovascular health, and anti-aging.

Understanding Coenzyme Q10 Quality Parameters

Quality assessment begins with evaluating the purity profile of your chosen supplier. Premium Coenzyme Q10 Powder Bulk should demonstrate purity levels exceeding 98% through validated analytical methods. HPLC testing reveals the true concentration while identifying potential impurities that could compromise formulation integrity.

Particle size distribution directly affects bioavailability and manufacturing consistency. Uniform particle sizing enhances dissolution rates and improves blending characteristics during capsule or tablet production. Advanced micronization techniques create optimal particle ranges for various delivery formats.

Controlling the moisture content stops decay while the goods are being stored and processed. By following the right drying and packaging rules, good providers keep moisture levels below 0.5%. This measure has a big effect on how stable something is on the shelf and stops oxidation, which makes something less effective over time.

Color consistency indicates proper handling and processing conditions. Pure ubiquinone powder exhibits characteristic white to pale yellow coloration. Darker hues often signal oxidation or contamination that compromises product quality and consumer acceptance.

Regulatory Compliance and Certification Requirements

Certifications that are awarded on an international level serve to confirm both the capacity of suppliers and the safety of their products in markets all over the world. By obtaining ISO 22000 certification, organizations are able to demonstrate that they have in place comprehensive food safety management systems that protect the integrity of their products throughout the whole manufacturing process. This standard guarantees that the process of identifying hazards and implementing control measures will be conducted in a methodical manner.

HACCP implementation provides structured approaches to biological, chemical, and physical hazard prevention. Suppliers with robust HACCP systems minimize contamination risks and maintain consistent quality standards. Documentation requirements support regulatory submissions and audit processes.

Halal and Kosher certifications expand market accessibility for religious dietary requirements. These certifications require independent verification of ingredients, processing methods, and facility management practices. Religious compliance opens opportunities in specialized market segments.

BRC Global Standard for Food Safety addresses international retail requirements and supply chain management. This certification demonstrates commitment to quality culture, product safety, and operational excellence. Many multinational brands require BRC certification from raw material suppliers.

Organic certification helps to promote the positioning of natural products and the customer preferences for ingredients that are more sustainable. In order to be considered certified organic, Coenzyme Q10 Powder Bulk must adhere to stringent production requirements, which include the prohibition of synthetic pesticides and genetic manipulation.

Manufacturing Technology and Production Methods

Fermentation technology produces the highest quality ubiquinone through controlled microbial processes. This method yields identical molecular structures to naturally occurring coenzyme Q10 found in human cells. Fermentation eliminates synthetic chemical residues while ensuring consistent potency.

Advanced extraction and purification techniques remove unwanted byproducts and concentrate active compounds. Multiple purification stages create pharmaceutical-grade materials suitable for demanding applications. Crystallization processes enhance purity while maintaining molecular stability.

Quality control laboratories equipped with sophisticated analytical instruments verify every production batch. Mass spectrometry, nuclear magnetic resonance, and infrared spectroscopy confirm molecular identity and structural integrity. These analytical methods detect trace impurities invisible to standard testing.

Contamination can be avoided and appropriate conditions for processing can be maintained by the implementation of environmental controls during the production process. Sensitive compounds are safeguarded from deterioration by the use of temperature, humidity, and atmospheric controls. The risk of microbiological contamination can be reduced to a minimum in clean room situations.

Application-Specific Formulation Considerations

Cardiovascular health formulations require highly bioavailable forms that enhance absorption and cellular uptake. Coenzyme Q10 benefits include supporting heart muscle function and protecting against oxidative stress. Solubility enhancement techniques improve therapeutic efficacy in cardiac support supplements.

Anti-aging cosmetic applications demand exceptional stability and skin penetration characteristics. Coenzyme Q10 skin care products utilize specialized particle sizes and delivery systems. UV protection during processing prevents photodegradation that reduces cosmetic effectiveness.

Energy support supplements leverage coenzyme Q10 for energy production at cellular levels. Mitochondrial function depends on adequate ubiquinone availability for ATP synthesis. Optimized dissolution profiles ensure rapid absorption and metabolic utilization.

In order for sports nutrition products to be effective, they need to have a quick rate of bioavailability and a consistent release of energy. While allowing for controlled release mechanisms, specialized coating technologies serve to safeguard active chemicals. The aforementioned formulations provide assistance to both endurance performance and the processes involved in recovery.

Supply Chain Management and Sourcing Strategies

Reliable supply chains ensure consistent availability and pricing stability for long-term product development. Established manufacturers maintain adequate inventory levels and production capacity to meet growing demand. Supply agreements should include quality specifications and delivery schedules.

Geographic diversification reduces supply chain risks and provides alternative sourcing options. Multiple qualified suppliers prevent production disruptions during facility maintenance or regulatory changes. Supplier audits verify manufacturing capabilities and quality systems.

Raw ingredients are tracked from their origin all the way through to the completed goods by traceability systems. Thorough documentation provides help for both compliance with regulations and quality investigations. When it is required, electronic batch records make it possible to quickly withdraw products from the market.

The process of cost optimization strikes a compromise between quality objectives and budget limitations. Agreements for bulk purchasing offer discounts based on the quantity purchased while also ensuring that quality criteria are met. In the event of a scarcity in supply, long-term relationships frequently result in more favorable price and priority allocation.

Analytical Testing and Quality Assurance Protocols

Identity testing confirms molecular structure and eliminates raw material substitution risks. Spectroscopic methods provide definitive identification beyond visual inspection. Certificate of analysis documentation should include complete testing results and specifications.

Microbiological testing ensures product safety and regulatory compliance. Total plate counts, yeast, mold, and pathogen testing protect consumer health. Sterilization processes may be necessary for sensitive applications or immunocompromised populations.

Heavy metal analysis detects potential contamination from environmental sources or processing equipment. Lead, mercury, cadmium, and arsenic levels must comply with international safety limits. Atomic absorption spectroscopy provides accurate quantification of metallic impurities.

Shelf life under a variety of storage settings can be predicted by utilizing stability testing. The effects of long-term storage on purity and potency are replicated in accelerated aging trials. These investigations provide direction for the selection of packaging and storage suggestions in order to maximize the performance of the product.

Conclusion

In order to select Coenzyme Q10 Powder Bulk that is of good quality, it is necessary to conduct a systematic examination of the purity of the product, the methods that were used to manufacture it, the extent to which it complies with regulations, and the capabilities of the provider. Partnerships with certified manufacturers who are knowledgeable about worldwide quality standards and offer complete technical support are essential to the successful development of nutraceuticals. It is the amount of money that is invested in premium raw materials that ultimately defines how effective a product will be, whether or not it will be successful in obtaining regulatory approval, and whether or not it will be accepted by the market. In order to preserve competitive advantages in the expanding coenzyme Q10 market, research and development teams can create novel formulations that satisfy the demands of consumers by placing a greater emphasis on the factors of quality and the qualifications of suppliers.

Partner with Avans for Premium Coenzyme Q10 Powder Bulk Supply

Avans NutriHealth delivers exceptional quality and comprehensive support for your nutraceutical development projects. Our advanced fermentation technology produces high-purity ubiquinone powder with superior bioavailability and stability. With ISO 22000, HACCP, BRC, Halal, and Organic certifications, we meet the most demanding regulatory requirements across global markets.

Our team of seasoned researchers and developers works in close collaboration with our clients in order to come up with customized solutions that are in accordance with the specific formulation needs. Every single batch is guaranteed to undergo stringent quality control procedures by the most advanced analytical laboratories. We are a reliable supplier of Coenzyme Q10 Powder bulk, and we have a wide range of stock and a production capacity that can be adjusted to meet the deadlines of your project.

Ready to enhance your nutraceutical formulations with premium coenzyme Q10? Our technical experts are available to discuss your specific requirements and recommend optimal solutions. Contact us at Lillian@avansnutri.com to request samples and technical specifications for your next project.

References

1. Crane, F.L. (2001). Biochemical functions of coenzyme Q10. Journal of the American College of Nutrition, 20(6), 591-598.

2. Bhagavan, H.N., & Chopra, R.K. (2006). Coenzyme Q10: absorption, tissue uptake, metabolism and pharmacokinetics. Free Radical Research, 40(5), 445-453.

3. Molyneux, S.L., Florkowski, C.M., George, P.M., Pilbrow, A.P., Frampton, C.M., Lever, M., & Richards, A.M. (2008). Coenzyme Q10: an independent predictor of mortality in chronic heart failure. Journal of the American College of Cardiology, 52(18), 1435-1441.

4. Zhai, J., Bo, Y., Lu, Y., Liu, C., & Zhang, L. (2017). Effects of coenzyme Q10 on markers of inflammation: a systematic review and meta-analysis. PLoS One, 12(1), e0170172.

5. Raizner, A.E. (2019). Coenzyme Q10 for patients with cardiovascular disease: JACC Focus Seminar. Journal of the American College of Cardiology, 73(9), 1063-1078.

6. Tiano, L., Belardinelli, R., Carnevali, P., Principi, F., Seddaiu, G., & Littarru, G.P. (2007). Effect of coenzyme Q10 administration on endothelial function and extracellular superoxide dismutase in patients with ischaemic heart disease. European Heart Journal, 28(18), 2249-2255.